- Home page

- Decking Quality Description

PLANED THERMOWOOD PRODUCT QUALITY DESCRIPTION

| Raw material: | Pine (Pinus Sylvestris), Spruce (Picea Abies) |

| Thermal modification: | Thermo D-class (+212 °C) |

| End use: | Decking, exterior and interior cladding, landscaping |

| Moisture: | 6 % ± 2 % after production, in our yard |

| Allowed planing tolerances: | Width ± 0.5 mm

Thickness ± 0.5 mm Length – 10 mm, +30 mm |

| Possible dimensional swelling and shrinkage because of relative air humidity: | 5-6% |

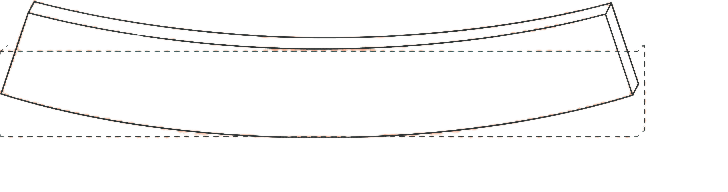

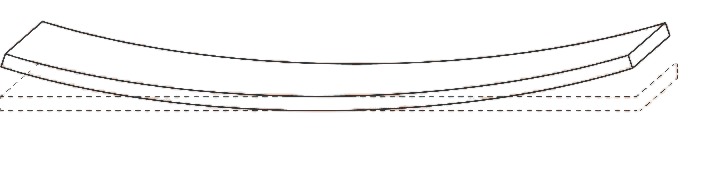

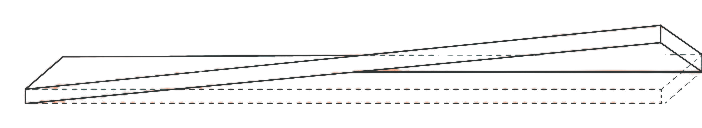

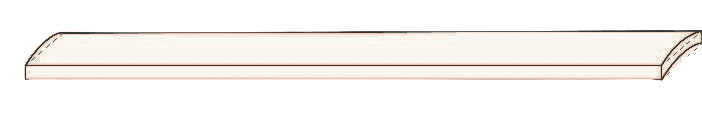

Allowed deformation tolerances:

GRADING

Three sides are graded – the top and the edges. The back is not graded, so any defects there are allowed if they do not compromise the integrity of the board and do not attect the good side of the board.

AB GRADE

This grade is made from AB grade raw material that has been planed but not graded. AB grade may contain up to 30% B grade boards.

A GRADE

The impact of a single defect is assessed by looking at the overall quality of the product.

Completely fallen branches are not allowed on the board, but split branches may occur. The ends of the boards may be cracked. Natural colour variations are allowed, the number of live knots is not limited, the heartwood line is visible. A few flaws are acceptable if the board looks good overall.

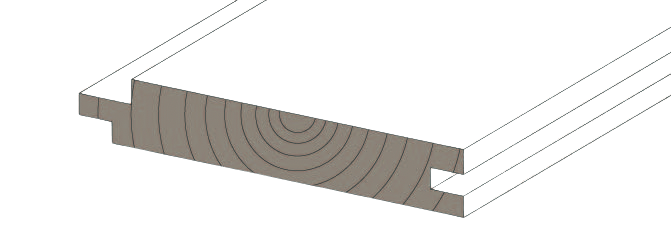

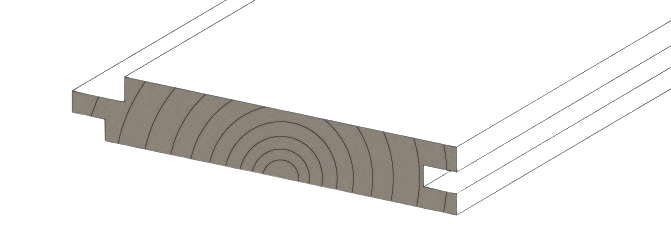

After installation, the visible parts of the tongue & grove must be

intact. Cracks hidden in the grove are tolerated. 8 cm at the end of the board are not graded (this does not apply to boards with t&g at the ends).

The surface of the boards must be smooth and presentable. A board is not suitable if its general appearance ditters significantly from the grade description.

B GRADE

In general, B grade boards have a good appearance. However, individual pieces do not meet A grade requirements because the boards have one or more major defects.

Completely broken pieces are not accepted in B grade.

B grade can easily be upgraded to A grade by cutting ott the defects.

C GRADE

C grade consists of rejects that do not meet the parameters of B grade. The boards may be broken, have severe longitudinal cracks, many empty knotholes or other severe mechanical defects.

ATTENTION!

Boards that do not conform to the grade description cannot be cut or otherwise used. Until evaluated, the products must be stored ott the ground on a level surface and protected from UV rays. If these instructions are not followed, the boards will not be replaced.

All grades may contain 3% defective boards.

Any quality complaints must be made within 14 days of delivery.

If You need more information, please contact our nearest sales department.

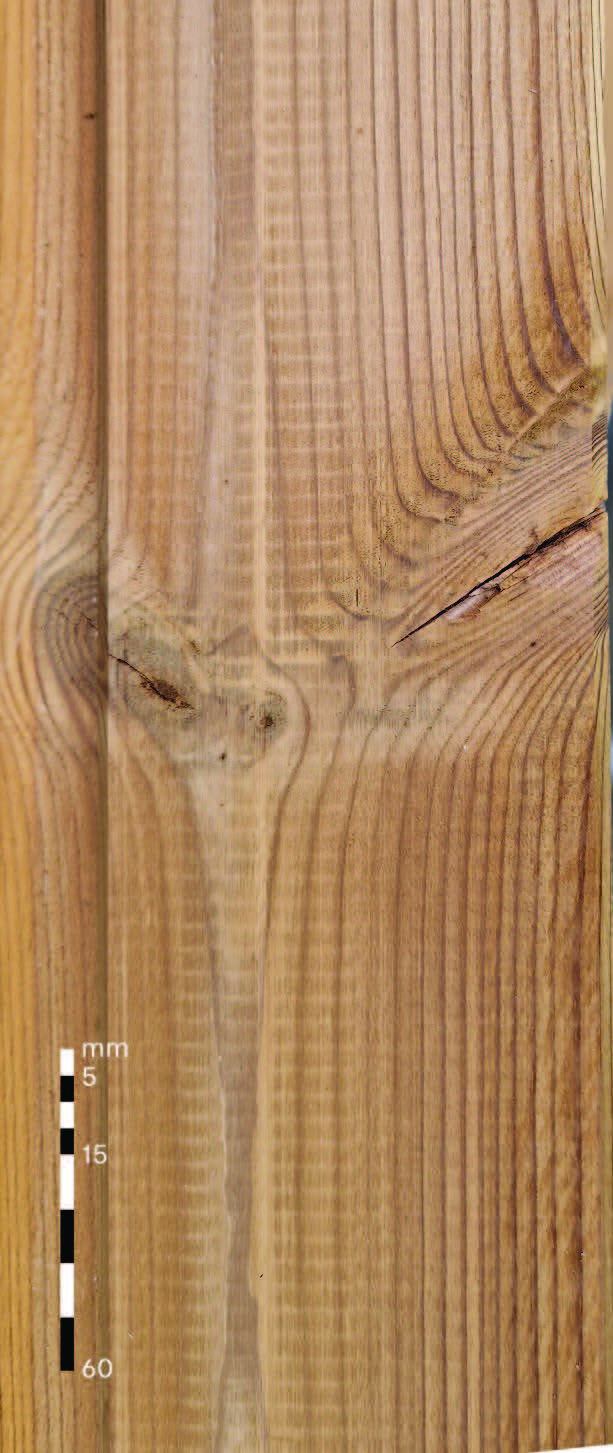

Sound knots

A grade: Allowed, unlimited

B grade: Allowed, unlimited

Knot cluster

A grade: Allowed, unlimited

B grade: Allowed, unlimited

Dead black knots

A grade: Allowed, up to 1/10 board width

B grade: Allowed, unlimited

Knot shakes

A grade: Allowed, up to 5 mm wide & 50 mm long

B grade: Allowed, unlimited

Knot shakes on the edges

A grade: Allowed, up to 1/10 board width

B grade: Allowed, unlimited

Knots with perimeter crack

A grade: Allowed, up to 0 20 mm

B grade: Allowed, unlimited

Knotholes on the sides

A grade: Allowed, up to 15 mm wide

B grade: Allowed, unlimited

Cracked knots

A grade: Allowed, up to 1/10 board width

B grade: Allowed, unlimited

Knotholes

A grade: Not allowed

B grade: Allowed, up to 0 20 mm, max 1 pc. x board length, m

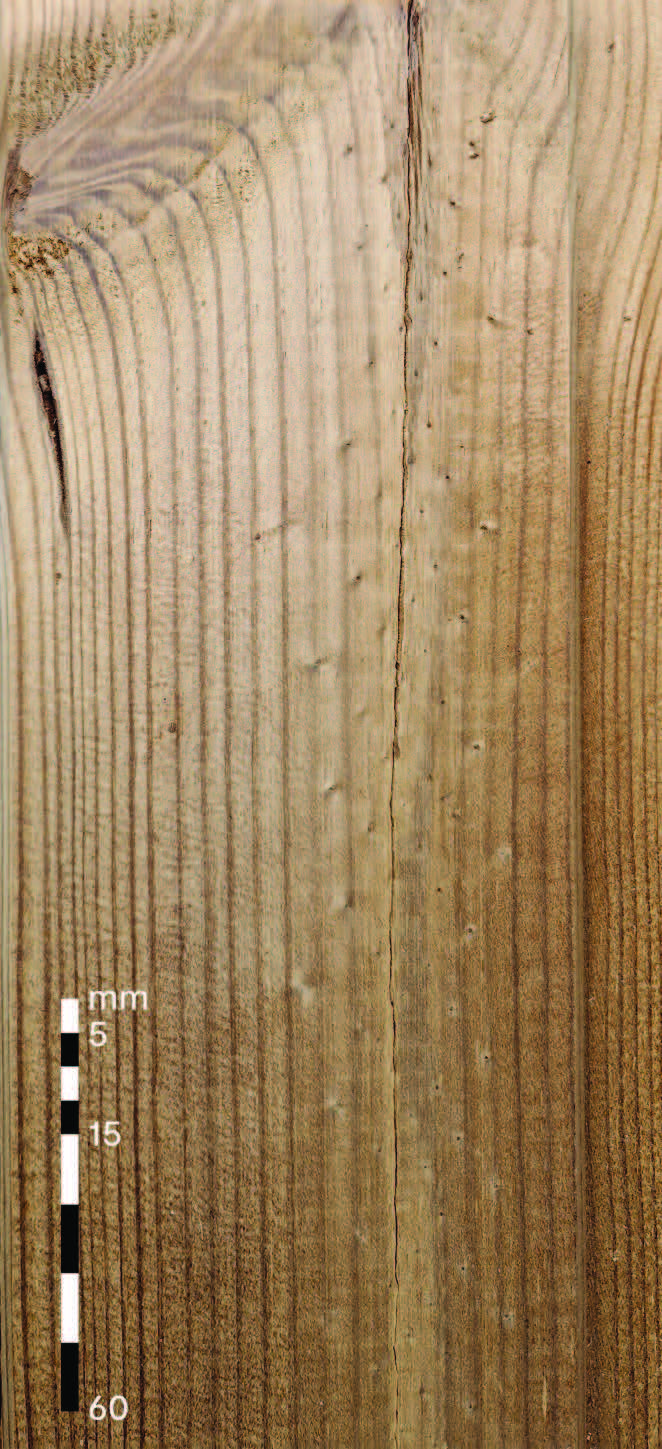

Feed-roller marks (from 0.5 mm deep)

A grade: Not allowed

B grade: Allowed, unlimited

Mechanical defects

A grade: Not allowed, except 80 mm ends of board

B grade: Allowed, up to 300 mm long, max 0,5 pc. x board length, m

Surface cracks

A grade: Allowed, up to 150 mm long

B grade: Allowed, unlimited

End splits

A grade: Allowed, up to board width

B grade: Allowed, up to 300 mm

Bark knots

A grade: Allowed, up to 1/3 board width

B grade: Allowed, unlimited

Sound heartwood

A grade: Allowed, unlimited

B grade: Allowed, unlimited

Dead heartwood*

A grade: Allowed, unlimited

B grade: Allowed, unlimited

*it is removed if surface is brushed

Resin pockets

A grade: Allowed, up to 200 mm long

B grade: Allowed, unlimited